描述

Regarding our four types of solder pastes, the differences and characteristics of high temperature, medium temperature, and low temperature usage:

1. M9: lead-free silver/environmentally friendly/high-temperature 217 ° solder paste

Usage tips: Suitable for technicians with high requirements for maintenance quality, reducing rework. However, due to the high temperature, the difficulty of maintenance will also increase.

Features: High temperature of 217 ° C, containing silver components, fine and sticky, non foaming of tin planting, uniform solder beads, firm welding, and environmentally friendly.

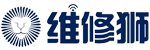

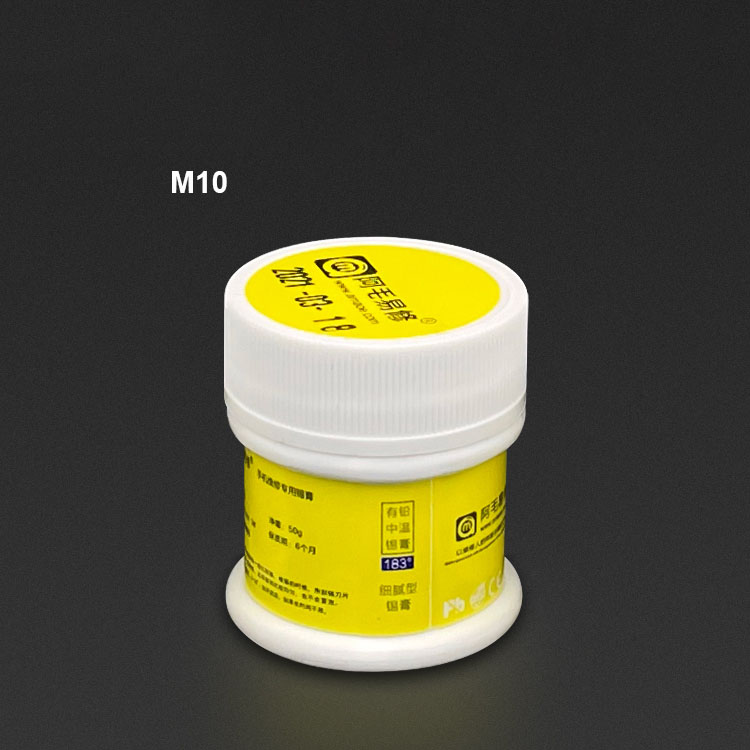

2. M10: with lead/medium temperature 183 ° C/solder paste

Usage tips: Suitable for regular phone repair and use, reducing rework.

Features: Medium temperature of 183 ° C, fine and sticky, no blistering during soldering, and even solder beads.

3. M11: lead-free/low temperature 138 °/solder paste

Usage tips: Suitable for repairing phones that cannot withstand high temperatures (such as the tin plating on the middle layer of the iPhone X motherboard), reducing repair difficulty and risk.

Features: Low temperature of 138 ° C, fine and sticky, no blistering of tin planting, uniform solder beads, reducing maintenance difficulty and risk, but welding firmness is not as good as medium to high temperature.

4. M13: silver containing lead/medium temperature 190 ° C/solder paste

Usage tips: Suitable for regular phone repair and use, reducing rework.

Features: Medium temperature of 190 ° C, containing silver components, with better firmness, conductivity, and glossiness, good delicacy and stickiness, non foaming of planted tin, and even solder beads.

评价

目前还没有评价